Healthcare expenditures comprise nearly 20% of the Gross Domestic Product (GDP). As such, it represents a huge target for companies that have achieved excellence in areas other than acute healthcare delivery- companies like Walmart, CVS, Walgreens and Amazon. These large and successful retail giants all have a few things in common- they know what they are doing, they do it well and they know how to make a profit doing it.

Each of these organizations consider the supply chain to be an important component of their success. To them, the supply chain is an essential element of their focus. Each has developed expertise in the supply chain at a level most healthcare organizations cannot even imagine. Each has economies of scale and ready resources for every aspect of the supply chain- from Sourcing, Contracting, Purchasing and Acquisition to Warehousing, Logistics and Fulfillment. Their staffs are highly-trained and innovative. Their operations are used (and expected) to turning high profit margins).

They are ready to compete in the health care wars of the future.

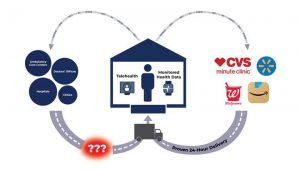

The graphic above features two channels of access to care-giving- the traditional Acute Care-centered model and the Non-Traditional vendor model. At the center of the graphic is the patient- armed with an electronic medical record (Monitored Health Data) and Telehealth. The patient, armed with data and access to diagnosis via telemedicine, has a choice of where to take his or her business- through the traditional portals of a health system or through non-traditional portals constructed by non-healthcare giants. The traditional pathway has its advantages:

The Non-traditional portal has its advantages as well:

The key to all of this is the man/woman in the middle of the central graphic- the consumer- known in the traditional model as the patient. Over the past decade, that consumer has adapted to new offerings in everyday life that have transformed the face of retail. Gone (or going) are the large malls. People shop from home via the internet and get exactly what they want- often within one to three days, and equally as often without a charge for that delivery.

All of this puts the consumer directly in the catbird seat. Catbird seat is an old phrase that refers to the behavior of the common catbird, who would find a secluded perch, make mocking calls, and decide how to take advantage of situations that develop. In the future, it is the plan of the big retail firms to create alternatives that will give the consumer the opportunity where to go for care- thereby placing the consumer in the catbird seat. They are banking on their ability to innovate, acquire talent, develop new approaches and market those new approaches successfully to the consumer more quickly and better that the traditional model can.

And an essential component of their strategy is a highly-functioning supply chain. As you look at the graphic, the dotted lines go from the consumer to the various possible providers of care- one to the traditional venues and the other to the new ones. All things being equal, the ultimate measure of success in the graphic is fulfillment, i.e.: the ability to successfully deliver the needed goods to the consumer on time, in the correct amounts and to the correct place(s) time after time. As you can see in the graphic, a singular strength of the retail giants is a proven history of excellence in fulfillment. Such is not the case in the abilities of the traditional care model.

Why?

Because for the retail giants- all of whom make profit margins in the double digits, the supply chain is recognized as a key component of the enterprise’s success. Their supply chains operate lean and efficiently. That efficiency and expertise contributes greatly to corporate bottom lines.

Too often in the past, the healthcare supply chain has been viewed as a support function and given secondary importance. If you are running your organization’s supply chain and your title says anything but Senior Vice President of Supply Chain (or at least, Vice President, Supply Chain), your organization does not consider Supply Chain a senior level function. Quite simply, if Supply Chain does not occupy a place at the highest level of decision-making in the organization, it can only be reactive, depending on those participating in a group it is locked out of to tell it what to do and often with whom to do it.

Evidence of where the Supply Chain stands in the eyes of the C-Suite was seen in a recent Becker’s article which focused on the “Top 5 concerns for healthcare boards”. They were:

Although the Supply Chain could be inferred to be present in point #2, no specific reference was made to the function. And while, as has been pointed out by others, healthcare boards are more strategic than operational, the simple fact remains that CEOs report to Boards and they keep their jobs by keeping the Boards happy.

Historically, Supply Chain has only received momentary days in the spotlight- when some kind of disaster such as a hurricane or a pandemic strike, and when financial disaster hits the bottom line. Once the crisis is surmounted, a return to “normalcy” in which the CEO’s primary goal is to keep the Board happy and thereby retain his job becomes priority number one.

The truth, however, is that the recent pandemic accelerated changes that were already afoot. It is an absolute given that the big guys in retail are coming- with all their resources, expertise and with their big guns blazing.

And you, Mr. or Ms. Healthcare Supply Chain Leader are going to have to quickly develop the skills necessary to give your organization a fighting chance.

Let us help

Over the last 38 years, we at St. Onge have helped countless organizations both within and outside healthcare plan the future of their supply chain operations. Through our design process, we perform an intensive level of due diligence to learn our clients’ needs. Site tours, detailed interviews and data drive the models and simulations we use to develop a thorough understanding of our client’s day-to-day activity from an efficiency perspective. This process validates our understanding of the client’s issues and provides the foundation for developing the relationships required to create innovative solutions.

St. Onge Company has grown steadily and developed a client list that includes many Fortune 500 companies and several world-renowned institutions. We have completed approximately 5,000 assignments for over 1,000 clients located through- out the United States, Canada, Mexico, the United Kingdom, Europe, the Middle East, the Far East, China and South America.

Our past projects cover a wide variety of Institutional, Commercial and Industrial applications for clients such as Johns Hopkins Hospital, Dana Farber Cancer Institute, MD Anderson Cancer Center, Rush University Medical Center, Duke University Medical Center, St. Jude Children’s Research Hospital and King Saud Abdul Aziz Hospital, as well as with their architecture firms. For these clients, we have developed a strong familiarity with the challenging logistics and related real-time issues associated with hospital operations, including campus supply chain strategies, materials management master plans, departmental optimization, facility designs and information systems to plan, direct and coordinate the movement of materials. Some of these solutions are highly automated; all are highly effective.

If you find yourself interested in developing a resilient supply chain operations strategy that will lead you into the post-COVID future, please contact St. Onge. Our experts stand ready to take a look at your operation and find the opportunities you may have overlooked. You can reach me at fcrans@stonge.com or call me at 563-503-1847.