Healthcare

Healthcare organizations of all sizes are facing mounting pressures that require an increasingly strategic focus to balance cost, quality of care and patient outcomes. Growing system scale and infrastructure complexity as well as shifting reimbursement and payment models mean healthcare providers must look at both labor and non-labor components of their service model to identify areas of opportunity.

At St. Onge, we approach healthcare operations improvement from an engineering perspective and focus on leveraging data and analytics to drive smart, informed decisions that deliver measurable results. Our healthcare clients count on our team for an unmatched blend of engineering and systems expertise that is combined with clinical healthcare experience.

Our best-in-class thinking takes our knowledge from supply chains across the industries we serve around the world and adapts and applies this information and our particular understanding of the healthcare industry and its regulations to the complexities and nuances that must be considered when evaluating improvement strategies.

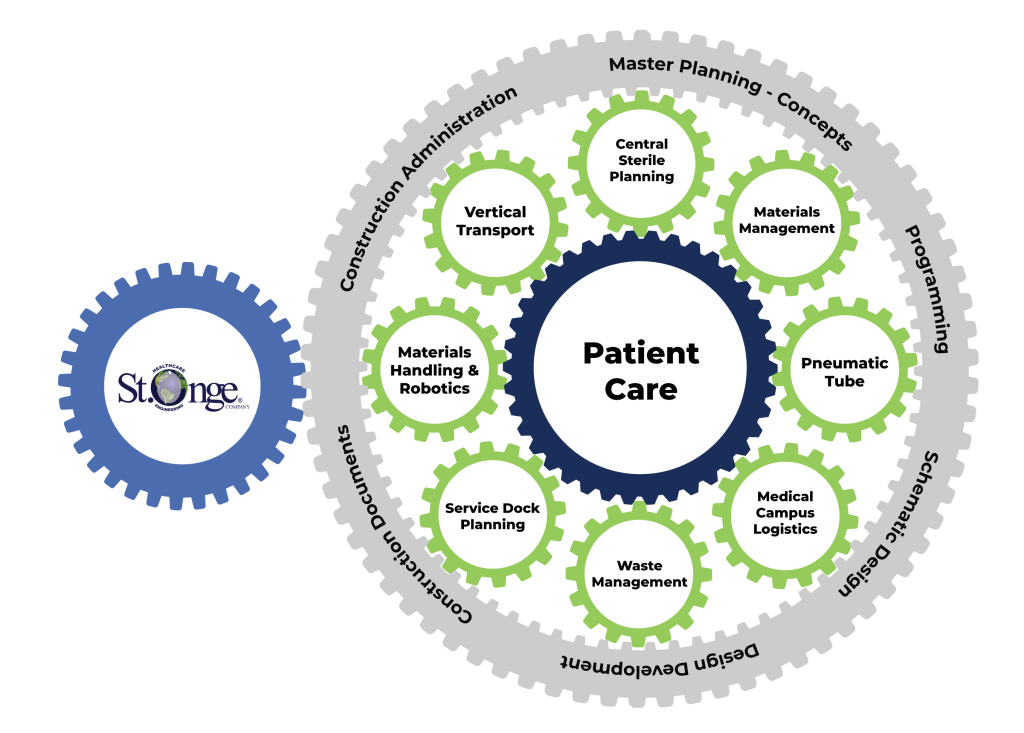

From planning and concept evaluation through implementation and return on investment reporting, we offer a comprehensive suite of healthcare and hospital improvement services including:

- Supply chain strategy and transformation to optimize capability

- Materials management solutions that deliver efficiency and enable world-class care

- Operational and continuous improvement projects to drive performance and efficiencies

- Facility planning and design encompassing new construction and facility renovations to engineer an efficient infrastructure that provides optimized returns for the full life cycle of the building

- Operational excellence planning to create foundational shifts in planning to drive ongoing improvements

- Vertical transportation including both new construction and existing facilities

- Pneumatic tube systems 30 plus years of healthcare pneumatic system design expertise from planning through construction.

- Central sterile processing our applied industrial engineering and operations research tools improve space utilization, equipment capacity, delivery reliability, infectious control, patient safety, and patient care

Focusing on Patient Flow and Experience

At St. Onge, our foundational healthcare expertise is enhanced by our depth of experience in patient flow and experience planning. Using a patient-centric approach, we identify opportunities to create efficiency while improving care across department lines. Check out our patient flow experience services to see how staff allocation, capacity and demand analysis as well as patient flow planning can lead to dramatic gains for your organization.

If you’re interested in seeing how strategies rooted in data-driven analysis can drive real results, check out how we’ve made an impact on our healthcare partners and connect with the St. Onge team to start a conversation.

Supply Chain

Pressures to deliver improved outcomes with less resources are on the rise in the healthcare industry. To not only survive but also thrive, organizations must leverage data and technology to create operational efficiencies across the supply chain network.

Smart supply chain planning can increase profits as well as productivity and ultimately boost gains in both employee and patient satisfaction. But, optimizing is no small task. The scale, complexity and continuous changes across healthcare supply chains means a strategic approach is critical to ensure transformation resources are applied in the right areas to make the most impact.

St. Onge’s independent engineering approach to supply chain management in healthcare is focused on taking time to understand the demands and opportunities specific to each supply chain – which means solving the right problems first! We consider the entire supply chain and offer comprehensive support from planning and evaluation through implementation and post-launch review. We leverage a data-driven engineering approach to evaluate systems, processes and technology across healthcare and hospital supply chains including:

- Materials management

- Logistics and distribution planning and optimization

- Value stream mapping

- Procurement

- Inventory optimization and replenishment

- Technology and automation management

- Process evaluation and planning

- Labor analysis

- Vendor management

- Purchased services evaluations

- Procure to pay process optimization

- Data management assessment

Through data analysis and simulation modeling, we are able to model and evaluate scenarios to develop solutions that will meet the goals of today and create a foundation for future success. This approach enables insight to how consolidations and transformations impact the model of care. Our team of independent consulting engineers has the ability to lead the process from strategy through implementation and evaluation. Services range from evaluating a specific component of the supply chain to a total system evaluation.

Smart strategies to guide healthcare and hospital operations improvements are increasingly critical as supply chain complexity grows and spending in the category increases. If you’re looking for opportunities to drive efficiency, reach out to the healthcare team at St. Onge and check out our case studies to see how we’ve made an impact for organizations around the world.

Materials Management

Successful materials management is a critical element of enabling world-class care in healthcare organizations. Having the right supplies, tools and equipment where the clinical team needs them, when they need them, ensures ease of access, efficiency and ultimately staff and patient satisfaction. The St. Onge approach to healthcare materials management is founded in strategies informed by data analysis and applied system engineering.

Across management of medical supplies, food, equipment, linens and waste, our team takes a total 360-degree view, from procurement to the bedside, to uncover the big buckets of opportunity that will drive measurable results in efficiency, cost reduction and service quality considering:

- Material stream mapping

- Storage and handling

- Inventory control

- Order processing and replenishment

- Purchase ordering

- Receiving and distribution

- Charge capture

- Evaluation and deployment of off-site Consolidated Service Centers

- Technology and automation

We know materials management systems and processes have profound impacts across your supply chain and patient care experiences in nearly every staff and patient interaction each day. At St. Onge, our system-wide view of materials management understands that true optimization success means looking across departments to uncover the systems, processes and technologies that create efficiencies, allowing clinical staff to spend less time focusing on supply needs and more time on their core competencies.

We use data and analytics to understand the current state of materials management within your organization and employ smart planning informed by lean management principles and subject matter expertise to map true supply and demand models, findings solutions that deliver balance in speed, efficiency and cost. Where appropriate, we use simulation modeling and real-time location systems (RTLS) data to drive improvement recommendations.

Materials management teams are faced with rapidly escalating cost pressures compounded by increasing complexity and delivery service level demands. St. Onge can help. Through our industrial engineering and lean management approach, we develop and deploy high value solutions that deliver measurable results.

Ready to ramp up efficiency? Reach out. We look forward discussing how we can add value to your organization.

Operational & Continuous Improvement

Balancing the needs of today with the performance expectations of tomorrow is a major task for any company, but of particular significance for healthcare organizations who are continually challenged to generate better outcomes with less resources. To be successful, it requires a continuous focus on optimization and leveraging real-life data and analytics along with a commitment by leadership and the team to an improvement mindset.

At St. Onge, we support organizations in building a foundation for successful operations. Once that foundation is in place, we help to execute and manage continuous improvement efforts to drive measurable results. From operational excellence planning to process monitoring and evaluation to patient flow and experience analysis, we deliver support at the total system level and more granularly when needed to help solve the right problems with the right solutions.

Our innovative data analysis tools and simulation technologies are at the heart of our ability to drive measurable results. In addition to electronic data and process observation, we use real-time location system (RTLS) data to capture the current state and analyze scenarios to drive improvements.

Our approach to operational improvement for healthcare doesn’t just treat the symptoms, we solve the root causes to achieve the best results. Using data, we work with the healthcare team to elevate the discussion to focus beyond the politics to the clinical problems. This approach enables an engaged and open dialogue around continuous improvement. We focus on educating staff on its importance and how it can drive meaningful change.

Having the right information at your fingertips makes the difference when it comes to smart planning and operational excellence for hospitals and health systems. So can having the right partner in place. Reach out to the healthcare specialists at St. Onge to discuss how we can work together to improve patient care and clinical staff satisfaction.

Facility Planning & Design

In today’s rapidly evolving market, new healthcare construction projects face increasing complexities from changing regulations, cost pressures, technology advancements and shifting patient demands. Making the most of capital construction investments means having a partner on your side who understands the demands of the industry and can help look across the total continuum of care to offer smart planning and design solutions that will set your organization up for success now and into the future.

Why choose St. Onge?

As a leader in strategic healthcare facility planning, clients trust St. Onge to deliver the expertise and support to guide new construction and renovation projects from master planning, concept design, programming, and facility design through procurement, construction and post-launch monitoring and evaluation.

- We look at the total picture, applying an unmatched depth of experience across healthcare supply chains, materials management, operational excellence and the patient experience.

- Our expertise includes service docks, materials management, environmental services, waste management and sterile processing operations and material handling solutions.

- We apply an engineering approach, using data and real-life analytics to map and analyze scenarios across your facility design, process flow and the patient experience.

- Looking across department lines, we consider the total picture and how new and revamped facilities can drive efficiencies.

- We have expertise in pneumatic tube systems, pneumatic waste and linen removal systems, autonomous mobile robots, automated guided vehicles and other material handling technologies.

- We evaluate technology and the application of automation, informing decisions backed by our commitment to ongoing research and development to stay at the leading edge of the industry.

- As independent engineers and consultants, we offer objective, unbiased analysis of providers, technologies and processes to match you with the solutions that offer the best fit.

- We bring unparalleled experience, applying world-class thinking with a customized approach to meet your individual facility and system needs.

- We understand how the demands of hospitals vary from those of outpatient care facilities and draw on our experience in healthcare facility operations, supply chain processes and patient experience to deliver optimized facility planning and design solutions customized to each client’s individual needs.

- We consider how safety, technology, sustainability and automation impact design, and we can execute detailed analysis and simulations using real-time location systems (RTLS) data that give you a true-to-life window into how decisions will impact ongoing operations.

Our commitment to smart healthcare facility planning and design as well as hospital facility planning and design helps to lower costs, optimize space and support improved patient care. We always dig deeper to find the best solution. Check out our healthcare projects to see how we’re making an impact for partners across the industry.

Whether you have a project on the horizon or one that’s underway and in need of strategic support, reach out to start a conversation about how St. Onge can add value as a partner in your facility planning and design initiatives.

Operational Excellence Planning

In today’s rapidly-evolving healthcare industry, consolidation, escalating economic pressures and shifting patient expectations are driving the need for organizations to engage in thoughtful and strategic planning that balances the needs of today with the long-terms goals of the future.

To take organizations from good to great, planning must push beyond departmental silos to uncover cross-functional challenges and opportunities. It must be fueled by a culture of continuous improvement and a desire to empower leadership and staff to take an active role in ongoing development.

At St. Onge, our approach to healthcare operational excellence is founded on a detailed understanding to help organizations create the basis for meaningful change.

- We know you can’t manage what you don’t measure, so we help define what key performance indicators should be in place and how they will be measured and communicated.

- We understand transformation takes time and measuring return on investment is critical, so we help organizations map an operational excellence strategy that is customized to their specific operations and their goals.

- We believe a successful plan must be sustainable Operational excellence efforts can fall short if teams are misaligned or if accountability and ownership aren’t clear across departments. We help map plans that deliver results for ongoing viability and success.

- We commit to delivering the best experience and expertise to the partners we serve, always staying at the forefront of industry priorities and metrics.

- We bring best-in-class thinking including innovative data analysis and simulation tools to give you the best information to make the right decisions.

Operational efficiency, cost control, safety, staff satisfaction, communication and patient experience – all of these and many more can see ongoing improvements as a result of effective operational excellence planning. If you’re looking to chart a course to move your organization forward, get in touch. We look forward to helping you get there.

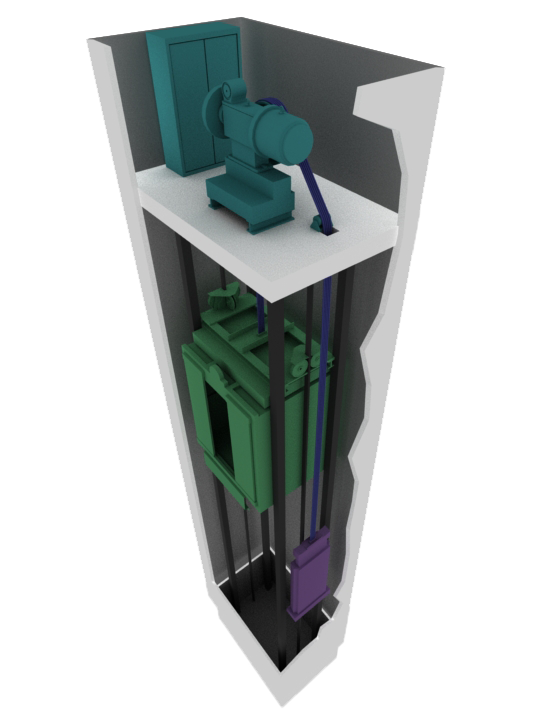

Vertical Transportation

Balancing the needs of today with the performance expectations of tomorrow is a major task for any company, but of particular significance for healthcare organizations who are continually challenged to generate better outcomes with less resources. To be successful, it requires a continuous focus on optimization and leveraging real-life data and analytics along with a commitment by leadership and the team to an improvement mindset.

Whether you’re looking to build a brand new facility or improving existing workflows, we can help you elevate your process to the next level. We know successful facilities are far more than what’s inside four walls. Connect with the St. Onge team and let’s start improving how your facilities work.

New Construction

Master Planning & Programming

- Equipment capacity and needs analysis

- Functional narrative

- Schematic Design Services

- Program validation

- Design coordination

- Building infrastructure (cores, pitts, overhead)

Design Development

- Equipment application detail

- Design drawing coordination(dimensions, MEP, and Technical specifications)

Construction Documents and Administration

- Final bid specifications and drawings

- CD submissions for vertical transportation

- Shop drawing reviews

- Construction site visit and installation review

- Punch list management and construction closeout

Existing Facilities

Traffic Analysis

- Handling capacity and wait times

- User-InterfaceEquipment Maintenance Audits

- Existing condition of equipment

Master Planning

- Prioritization of equipment modernization

Modernization Studies

- Design specifications, drawing review through construction progress visits

Code Compliance Audits

Operational efficiency, cost control, safety, staff satisfaction, communication and patient experience – all of these and many more can see ongoing improvements as a result of effective operational excellence planning. If you’re looking to chart a course to move your organization forward, get in touch. We look forward to helping you get there.

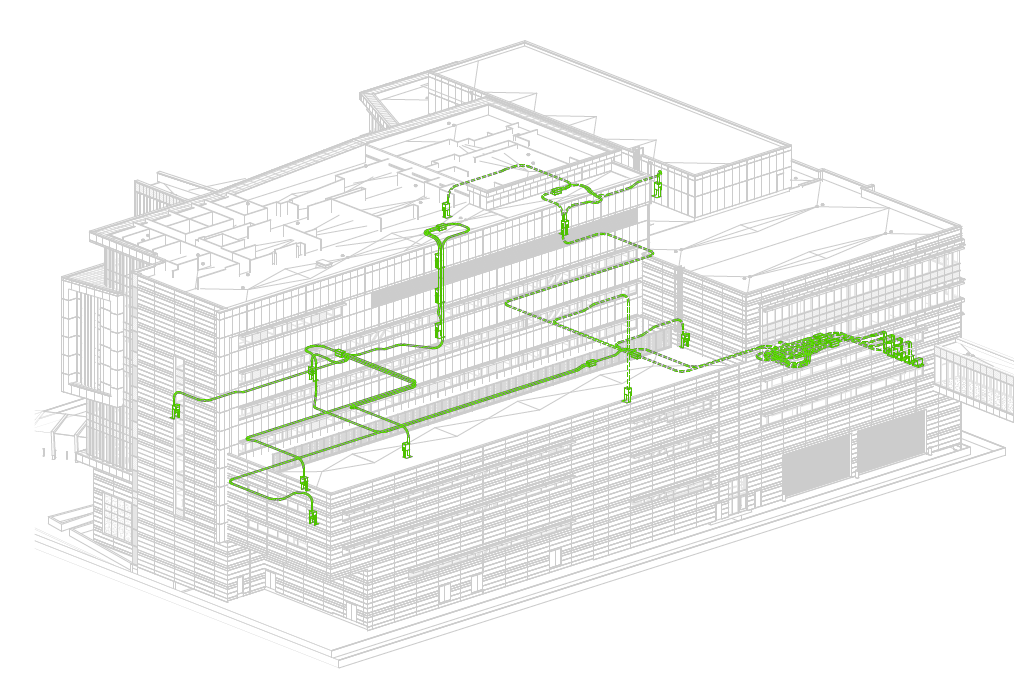

Pneumatic Tube Systems

As an independent engineering firm St. Onge Company, brings a client centric view and 30 plus years of healthcare pneumatic system design expertise. Our team can drive planning with small system modifications up to large complex system designs. Our team can develop competitive bid packages or vendor specific design packages. Our systemic view of complex operations with system capabilities, give us the edge on detailed pneumatic tube system design and planning services.

Key Service Offerings:

- Planning and Design Services

- Conceptual master planning for system expansion

- New Technology and Future Planning

- Detailed system design services

- BIM coordination

- Feasibility studies

- System Audit and Review

- Vendor Peer Review Services

- Construction Services

- Review vendor bid packages and pricing

- Respond to vendor “Request for Information” (RFI)

- Review vendor change order requests

- Review system installation and commissioning activities

Central Sterile Optimization

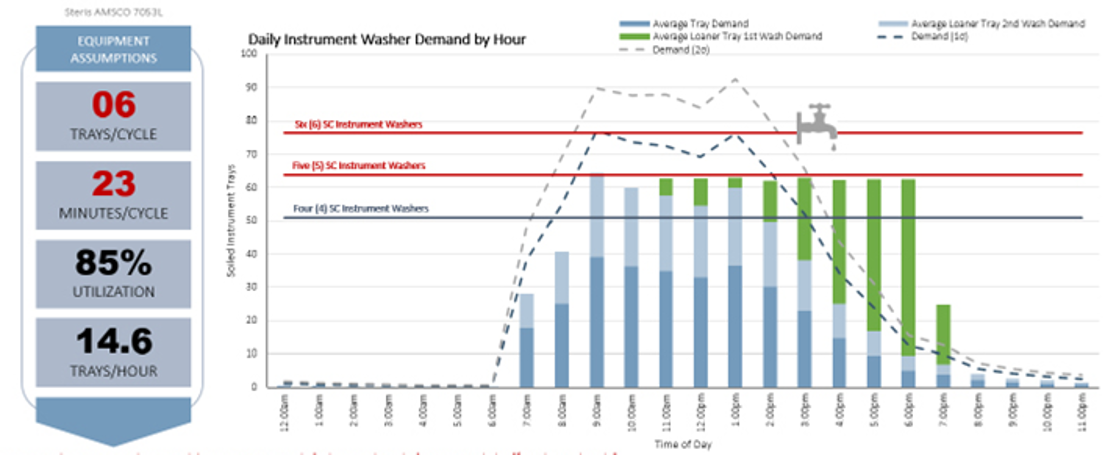

St. Onge Company capabilities in Central Sterile Processing (CSP) include applied industrial engineering and operations research tools and techniques to provide a systemic view of the complex interdependencies within the department to improve space utilization, equipment capacity, delivery reliability, infectious control, patient safety, and patient care.

The St. Onge team brings several key offerings to the world of Sterile Processing:

- Process Auditing and Benchmarking

- Value Stream and Process Mapping of Current State Operations (Departmental and with Critical Adjacencies) Data Analysis of Case Data to Determine Case Load and Timing by Specialty and Procedure

- Advanced Inventory Analysis by Discrete Item (Supplies, Instruments) to Determine Optimal Days on Hand, Storage Media, and Inventory Location

- Detailed Evaluation of Case Cart Requirements that Drive Optimal Delivery Sequences, Vertical Transportation, Staging Requirements, and Processing Procedures (Cart Wash, Instrument Tray Wash, etc.)

- Staff Productivity Benchmarking and Work-Flow Optimization

- Staff Scheduling and Demand Capacity Matching

- Discrete Event Simulation Modeling (Departmental and with Critical Adjacencies)

- Address and Correct any Infectious Control or Patient Safety Procedural Concerns (Flashing, Mixed Use Vertical Transport, etc.)