Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

During Promat, the Mobile Automation Group (MAG) which is one of many industry groups offered by MHI, conducted a seminar regarding maximizing vertical storage. Vertical storage solutions can increase efficiency, reduce long-term costs, and even provide a safer work environment by maximizing your existing space. VNA (Very Narrow Aisle) racking and fork trucks dominated the conversation. VNA rack guidance systems, rail or wire, are used to optimize speed and reduce product, rack, and vehicle damage. With a rail guidance system, the vehicle travels between rails mounted on both sides of the aisle at the base of the rack. Guide rollers mounted on the sides of the lift truck mechanically control the truck travel path with the aisle. On the other hand, a wire guided system is installed with a wire buried in a groove in the center of the aisle floor. The wire produces a magnetic field which steers the progress of the truck. The steering is completely automatic when the vehicle is locked on the wire.

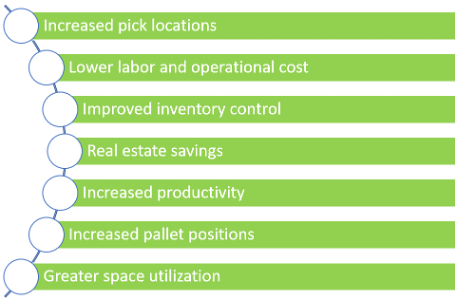

The advantages of VNA systems can include the following:

Since VNA systems can create additional levels of racking storage, and the distance across the width of the travel aisle is reduced dramatically, floor flatness plays a major role in safety and efficiency. Both a specialist design and construction approach are needed to attain the floor flatness requirements for VNA applications. Defined traffic floors must be extremely flat. If there is too much variation in the floor’s flatness, and the distances between the lift vehicle and racking in the very narrow aisle are extremely small, variations in the floor’s flatness will result in the lift truck being out of plumb relative to the racking as the vehicles mast raises. This will result in a collision between the lift’s mast and the racking at height if the floor is not flat enough.

Choosing the right truck is equally vital as well.

There are three main types of narrow aisle lift vehicles: articulated counterbalanced forklifts, turret trucks, and order-pickers. Since VNA aisles can be less than 6ft wide, VNA vehicles must perform in extremely tight locations, whereas, conventional reach trucks require roughly 10ft aisles to allow them to turn into pallet storage locations. Unlike a reach truck, an articulated forklift provides the operator with a narrow aisle forklift and traditional counterbalance machine in the same unit. A turret truck can operate in a narrower aisle than a reach truck or articulated forklift. Turret trucks use swinging forks to turn into storage locations to access pallets. Man-up turret trucks allows operators to closely oversee placement of all pallets with high precision. With a man-up truck, both the forks and the operator move up and down. With a man-down truck, the operator stays at ground level while the forks move up and down. However, a turret is more expensive and, when not on their in aisle guidance, slower than both reach trucks or articulated machines. Order pickers are designed for case or piece picking directly from storage positions and non-pallet handling.

In conclusion, one of the best ways to boost your warehouse’s storage capacity given its existing space is to take advantage of vertical storage solution to maximize efficiency – all of which can lead to significant ROI. VNA systems help to optimize space for storage and less for aisles, enabling approximately 50% more storage compared to conventional racking systems. With the surge of warehouse rents increasing as demand for industrial space increases, not only the United States but also around the globe, VNA racking and vehicle solutions are on the rise.

—Ashley Rhodes, St. Onge Company