Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

Following up from last week’s blog post (link here) introducing Environmental Social and Governance (ESG), this week we are diving into the “E” and the relevance to supply chains.

By now everyone has heard about sustainability and supply chains, both independently and jointly (separately and their interdependence?). Originally defined by the United Nations in 1987, sustainability means, “meeting the needs of the present without compromising the ability of future generations to meet their own needs.” Given the emphasis on climate change, and the real risks of not achieving the latter part of that definition, businesses and individuals worldwide have been searching for ways to become more sustainable. We all have a part to play but organizational impacts can certainly move the needle further than an individual. Some industry supply chains can account for 80% of their greenhouse gas emissions so even small changes make a positive impact.

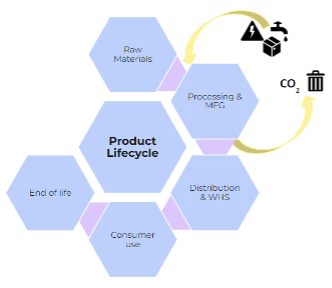

When looking at your organization’s supply chain, understanding a product’s lifecycle and potential impacts along the way are critical. This is referred to as a Lifecycle Assessment (LCA). Think about your end-to-end supply chain, tracing your product back to raw materials through its final use to a customer and its ultimate disposal.

See the image below for a sample product lifecycle and how the supply chain helps define that lifecycle. Each of these lifecycle stages has a series of inputs and outputs. The common inputs throughout the chain include energy, water, and packaging materials while common outputs include emissions (air or water) and waste. Emissions can be categorized as Scope 1, 2, or 3 depending on their direct or indirect relationship to operations (for more info on scopes 1 and 2, click here and for scope 3 click here). At each stage in the supply chain, these inputs and outputs can be measured to develop a baseline and these numbers can help illuminate the areas of opportunity for reduction, yielding a more sustainable product.

Here are some ideas on sustainable opportunities to explore at each of the supply chain stages. This list is not exhaustive but can help direct efforts to identify quick wins.

Despite the end of formal product lifecycle, there are more opportunities to continue exploring in the supply chain. As technologies continue improving, it’s important to stay abreast of opportunities to reduce emissions, explore circularity, and achieve zero waste.

—-Kira Bilecky, St. Onge Company