Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

When determining the methodology to identify each storage location uniquely within your distribution center, the primary goal is to allow a teammate to quickly understand the “battleship coordinates” of each location. The most reliable approaches predictably number aisles (e.g., from one side of the distribution center to the other) and consistently number sections within each aisle (such that low-numbered sections are at the same end of every aisle).

This matrix of aisle and section numbers will provide the X and Y axis necessary for teammates to quickly understand their current position within the distribution center and their relative position of any storage location.

Unfortunately, I often see distribution centers where location numbering was too influenced by pick-path considerations. A teammate’s pick-path is vitally important. In many warehouses, travel can account for up to 50 percent of the picking time. However, there are more effective methods to manage a pick-path within your facility. Attempts to address pick-path by only location numbering will compromise the overall matrix concept (described above) and provide only limited and inflexible pick-path features. Below are just a few facets you should deploy within your WMS to ensure your teammate’s travel path is productive.

Pick Sequence: A robust Warehouse Management System (WMS) will provide a separate location attribute to control the pick-path. Assigning a unique pick-sequence number to each storage location allows for greater control of the pick-path. For example, defining a:

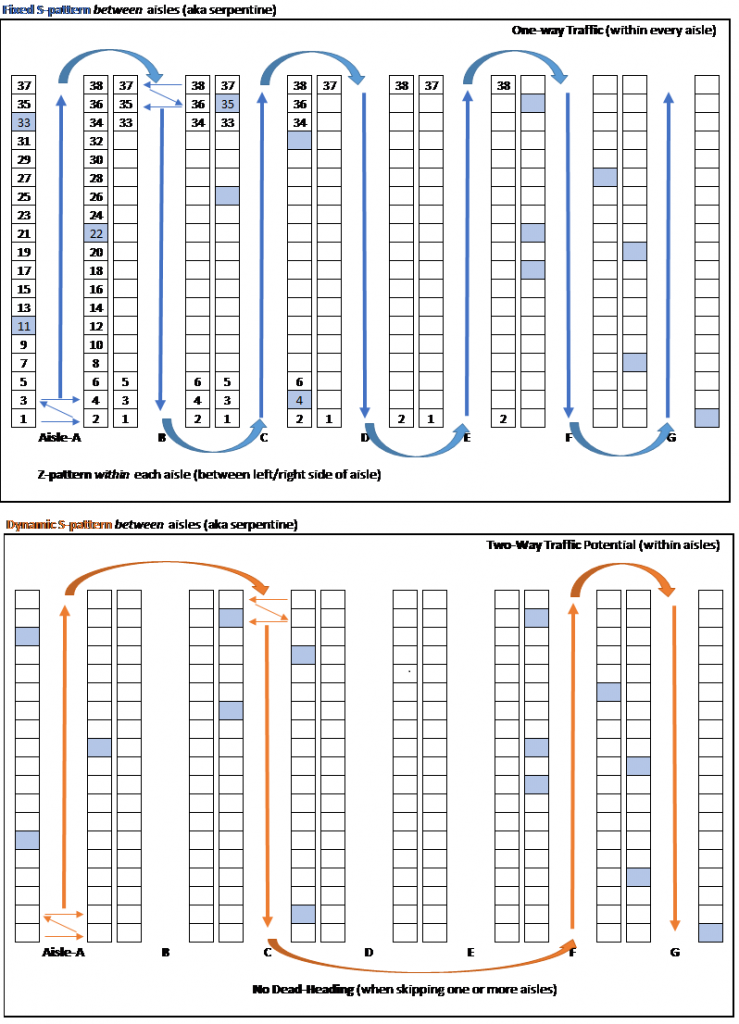

Dynamic S-Pattern: A best-in-class WMS will allow for dynamic S-pattern movement between aisles. Notice the same locations are highlighted within both images. In this example, the dynamic S-pattern method drastically reduced the overall travel distance by eliminating deadhead travel within aisles without a pick transaction. With this approach, be aware that there is the potential for two-way traffic within an aisle. If one-way traffic is required (because of aisle width) or desired (for safety considerations), a static S-pattern can support these goals.

Proximity: When establishing the pick-sequence for your warehouse, I recommend visualizing picking from every location – forward pick or random reserve. By prescribing a pick-sequence to all locations, concepts like “proximity” can apply to your put-away strategy. For example, if the lower level entails pick locations and locations overhead are intended to hold reserve inventory, the WMS can calculate the relative proximity of every reserve location to an item’s pick location. This calculation can help direct put-away to the closest available reserve location. Consider the favorable impact this approach will have on your team’s ability to ultimately perform a replenishment of the pick location. Please visit my prior blog entries for other put-away and replenishment concepts.

Travel Paths for Other Functions: A best-in-class WMS will provide the ability to define location sequence numbers beyond that which will control pick-path. There should be an option to define a separate sequence number to affect tasks like put-away and cycle counting.

Selecting a WMS that provides controls dedicated to managing travel within your facility will enable you to chart a path toward improving productivity.

— Kail Plankey, St. Onge Company