Strengthening your supply chain one link at a time.

Strengthening your supply chain one link at a time.

As organizations continue to turn to automation to reduce the negative impact of scarce labor and the accompanying higher costs, robots and automated storage and retrieval systems (ASRS) are in greater demand. Meeting customer demands of 2-day shipping, same-day shipping, next-day shipping, exacerbated by the holiday and peak seasons to process orders, requires real-time visibility to deliver on time and decrease cost. Smart warehousing solutions help organizations keep their warehouse organized, provide end-to-end visibility, and save costs.

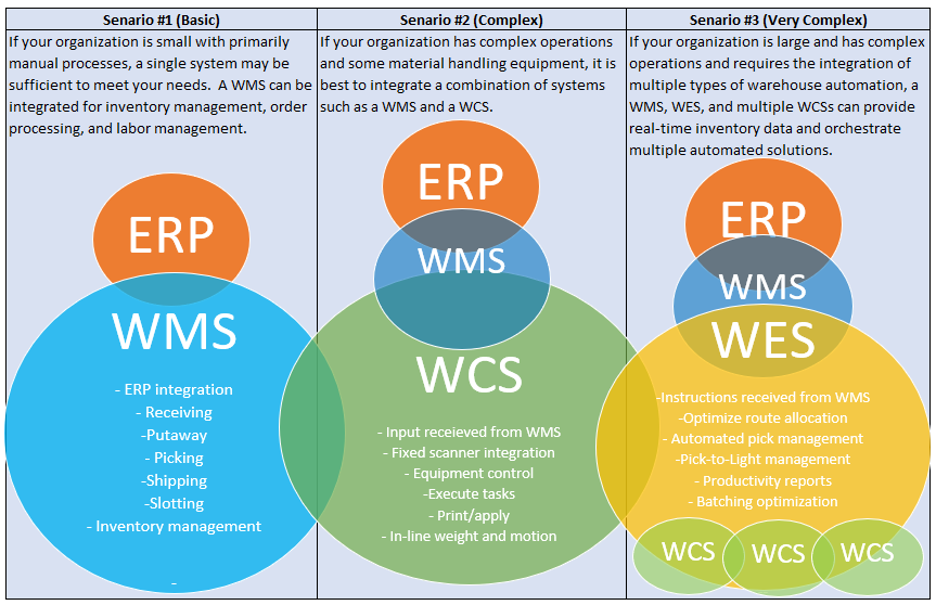

Demand for fast and precise order fulfillment requires warehouse managers to rely heavily on software such as warehouse management systems (WMS), warehouse control systems (WCS), and warehouse execution systems (WES). Warehouse managers must choose the right software solution to achieve cost-effectiveness, efficiency, and accuracy.

What’s the difference between WMS, WCS, and WES?

A WMS manages the inbound and outbound flow of goods and packages throughout a facility. Typically, a WMS provides system-directed picking, replenishment, putaway, packing, and other functions. Organizations can use a WMS to track inventory levels and the movement of products in real-time via the web or mobile app. A WMS delivers information about where the products are to be delivered, and the WCS executes the directions using automation.

A WCS communicates instructions to robots and ASRS to move, store, or retrieve products. A WCS controls all types of automated equipment such as conveyors and sortation systems. With proper maintenance, the life of material handling equipment (MHE) can be prolonged. A WCS can manage routine maintenance tasks by identifying real-time equipment defects and scheduling movements to reduce unnecessary depletion. It can regulate the speed and course-plotting of conveyor systems to enhance the flow of products through the warehouse.

A WES can combine the functionality of a WMS and a WCS. Oftentimes, there is an overlap between the three systems. A WES is a software solution that manages a portion of the WMS tasks through greater WCS capabilities which allows for improved control, reporting, and alerts of MHE. On the other hand, a WCS is customized specifically to manage MHE with fewer WMS capabilities. WES systems provide complex process optimization capabilities to improve productivity, efficiency, and throughput. A WES can coordinate all aspects of the following warehouse operations:

Consider the following when deciding which software solution would be best for your organization:

Keep in mind every warehouse is different in its needs, as determined by the order and processing demands and the equipment within the warehouse to satisfy those demands. It may one, or a combination of the systems above that provides the facility and operation with greatest benefit.

—Ashley Rhodes, St. Onge Company